Company's History

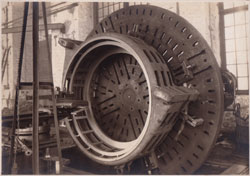

The company’s history started about a hundred years ago, when Carl and Christian Luther led the confirmation of the AS Volta founding charter on April 15, 1899. Construction of buildings on the bought lot started immediately and the company went into business on January 5, 1900. The factory was equipped with the most modern machinery at that time and Russian raw materials were used to manufacture electric motors and generators for the Russian market. The power capacity of the AC and DC generators was 1-330 hp.

The company’s history started about a hundred years ago, when Carl and Christian Luther led the confirmation of the AS Volta founding charter on April 15, 1899. Construction of buildings on the bought lot started immediately and the company went into business on January 5, 1900. The factory was equipped with the most modern machinery at that time and Russian raw materials were used to manufacture electric motors and generators for the Russian market. The power capacity of the AC and DC generators was 1-330 hp.

In 1909, Volta built three 250 hp steam turbines and three 250 hp and 3kV AC generators for Tallinn’s first power station.

In 1910, a portion of the shares was sold to the St. Petersburg Discount and Loan Bank as a result of which the company received large state orders for the railroad and military offices. In 1913, when AS Noblessner’s shipyard started its business, Volta manufactured all of the electrical equipment for the constructed submarines.

The product range was constantly updated and the total production grew. By 1916, the turnover reached 5.5 million roubles, a total of 860 workers were employed by the company and the management’s seat was transferred to St. Petersburg.

In the summer of 1917, the factory was evacuated to Russia: the employees, work benches and instruments to Perm, the rest of the property to Moscow and the factory was restarted a few years later in the Ural region in the community of Barantsinsk. The factory in Tallinn stayed empty for almost five years. The Republic of Estonia then enforced its maintenance on the company and gave a loan of 15 million marks to procure equipment and start production. The problems of the day for the company were the disrupted ties to the Russian market and the non-existent capacity of the Estonian market. Some rooms were rented to such companies as the Perfume Factory Feival, the Chocolate Factory Kawe, the Fetlt Factory Keila etc.

In the summer of 1917, the factory was evacuated to Russia: the employees, work benches and instruments to Perm, the rest of the property to Moscow and the factory was restarted a few years later in the Ural region in the community of Barantsinsk. The factory in Tallinn stayed empty for almost five years. The Republic of Estonia then enforced its maintenance on the company and gave a loan of 15 million marks to procure equipment and start production. The problems of the day for the company were the disrupted ties to the Russian market and the non-existent capacity of the Estonian market. Some rooms were rented to such companies as the Perfume Factory Feival, the Chocolate Factory Kawe, the Fetlt Factory Keila etc.

In 1939, the company employed 244 workers, there was no serial production, electric motors, transformers, pumps, ventilators, heating elements etc. were produced on the basis of orders.

On July 26, 1940 the factory was nationalized.

In 1941, the factory was disassembled and sent to Russia, however most of the equipment sank to the bottom of the sea with their ship transports.

In 1947, the factory was quickly reconstructed on the basis of trophy equipment and the aforementioned Keila and Kalev were ejected from the company’s territory.

In 1960, production started on a common line of electric motors and the production of generators was discontinued.

In 1963, 242000 electric motors, 70000 small motors, 190000 electric irons, 2000 wafer makers and 6700 radiators were produced.

In 1963, 242000 electric motors, 70000 small motors, 190000 electric irons, 2000 wafer makers and 6700 radiators were produced.

By the start of the 1980s, all of the current production units were finished.

In 1989, the production of asynchronous squirrel cage motors with the frame sizes of 132 and 160 mm exceeded 300000 and almost 70000 electric radiators were simultaneously produced with the plant located at Türi Alliku.

1990 saw the start of the reconstruction of the foundry: technical documentation and concrete parts were ordered, some of the previous buildings were demolished. The financing stopped with the dissolvement of the Soviet Union and half-built buildings were left behind.

1991 and 1992 were especially difficult for the factory, since it continued to supply Russian companies with electric motors on the basis of production plans, but money for them mostly never arrived.

In 1992, the Estonian Privatization Agency announced for the first time the company’s privatization at the international privatization auction, but despite the large interest no final offers were made.

By the end of 1993, the separate Türi Alliku plant in Paide was privatized to the registered public company MASI.

In September 1994, the Privatization Agency and Ravori Investeeringute AS signed a purchase agreement concerning the properties and parts of RAS Volta.

At the start of 1995, the Estonian Privatization Agency decided to liquidate RAS Volga with its order.

At the start of 1995, the Estonian Privatization Agency decided to liquidate RAS Volga with its order.

By May 1996, the Estonian Privatization Agency, the Tax Board and Ravori Investeeringute AS finalized in the privatization agreement the sum of the tax debts sold to the company.

In 1997, RAS Volga was erased from the company registry.

In 1998, all of the archived RAS Volga documents collected until 1994 were handed over to the Estonian State Archives.

In 1998, Ravori Investreeringute AS changed its business name to Elektrimasinaehituse AS.

By 2000, Elektrimasinaehituse AS had fulfilled all of its duties accepted with the privatization contract to the Estonian Privatization Agency and received the respective confirmation.

By the start of 2003, the pre-privatization tax debts had been successfully repaid to the Tax Board.

In 2003, Elektrimasinaehituse AS won a property debate about VOLTA that started in 1998 with AB Elektrolux.

In 2003, Elektrimasinaehituse AS changed its business name to AS Volta.

In 2003, Det Norske Veritas gave AS Volta the quality management certificate ISO 9001:2000.

In 2004, the Estonian Patent Office confirmed the registration of the trademark Volta in classes 7 and 9.

Economic Activity

In 1994, after the privatization of the company, the management assumed the direction of raising the effectiveness of the economic activity and separated the production and business projects. At first, seven daughter companies were formed for this on the basis of the companies departments. After a short period, two of those companies were decided to be liquidated due to the unsatisfactory economic results and three were merged with the parent company.

Today, AS Volta has an 80% share in two daughter companies – Volta Energeetika OÜ and Volta Kinnistute OÜ.

Also, Volta is an associate at the Tallinn Business Bank.

During 1996 – 1999, the following larger projects were carried out in production:

- A new electric motor wrapping plant (ca 600 m2) was built and equipped with the necessary machinery (about 160 units)

- In the forming plant, areas were prepared for the necessary assembly machines and two new forming lines were purchased.

- The usage of energy and labour intensive, amortized automated lines was stopped.

- A number of production machines, including all forming lines and aluminium foundry machines were renovated.

- Rooms were built for the department of electric motor repair.

In order to reorganize the company’s management structure:

- A computer network was built with 12 work stations

- A new storage and accounting program was bought from RV-Soft and implemented, enabling the link the work and reporting of the factory’s different subunits.

- A new system of work timekeeping and payment was introduced to constantly measure the overhead costs of production.

Significant dates in the company’s history

Alessandro Volta (1745-1827) builds a galvanic element – the Voltaic pile as professor of the University of Pavia, 1815

On April 15, 1899, the confirmation of AS VOLTA’s foundation charter in order to develop the electrotechnical industry of Carl and Christian Luther.

12% of the shares of the Riga Bank of Commerce

One of the owners of the Riga Bank of Commerce, Germany’s AEG (Allgemaine Elektrizitäts Gesellschaft) fixed capital 1.5 mil. roubles; other shareholders: Girard, Rotermann, Rosen, Ingmann

In 1900, the main building was ready, work started on January 5, 1900 under the leadership of the engineer Konrad Schindler from Switzerland.

In May 1901, post-project work was finished on the construction territory of about 10 ha. The factory is furnished with extremely modern German machinery (the first electric hammer in Estonia). Russian raw material is turned into electric motors for the Russian market.

In 1901, 174 workers 11 hours a day

In 1904, 264 workers with the salary of 30-35 roubles, (back then a loaf of bread costs about 0.01 rbl.)

Electrification work starts on the other companies in Tallinn: the Luther veneer and furniture factory, Dvigatel, the Kärdla felt factory, the Türi paper mill.

In 1909, construction starts on the Tallinn power station

AC and DC generators 1-330 hp and ball bearing AC electric motors are produced, the largest were 2000 hp generators.

In 1910, a proportion of the shares to the St. Petersburg Discount and Loan Bank. Recieves state orders for the railroad and military offices.

In 1911, 2000 electric motors are produced

In 1913, output is doubled - worth 2100000 rbl ( about 500 rbl/item), 5 companies in Tallinn and a factory in Riga supplied the factory with foundry products.

In 1913, started the construction of its own foundry.

In 1913, the AS Noblessner shipyard went into business, constructing submarines with Volta producing all of their electrical equipment.

New products – twin armature DC machines, electromagnetic connector, 14 engineers and 10 technicians in the factory.

In 1913, 760 workers

In 1914, 860 workers, the management moves to St. Petersburg

In 1914, AEG secretly plans to buy 51% of Volta’s shares.

In 1916, production worth 5500000 rbl.

In 1916, 600000 hand grenades produced.

In 1917, the shares are worth about 5 mil. rbl.

In the summer of 1917, the factory is evacuated to Russia: the employees, work benches and instruments to Perm, the rest to Moscow and St. Petersburg.

In 1925, Martin Luther and Karl Stark attempt to register „Eesti Aktsiaselts Volta”, but permission is denied.

Eesti Elektrimasinaehituse Aktsiaselts is registered and renamed Aktsiaselts Volta Tehased in 1936, produces electric motors, transformers, electric pumps, ventilators, heating elements.

No serial production, only individual orders.

In 1939, the company employed 244 workers with the average salary of 32 kroons, the skilled labourer got 90 kroons, the engineers 400, the director 700 kroons a month.

On July 26, 1940, the factory was nationalized – the worker Artur Alu became the factory director, the old administration and engineering-technical staff remained along with about 164 workers.

In 1941, the factory was disassembled and sent to Russia. Some of the machinery sank with the ships, during the war many small companies were located on the factory’s territory.

In 1947, the reconstruction of the factory and the completion of the machinery is finished. Keila and Kalev are ejected.

In 1951, the first automated line to process frames and the automated press for pressing stators and rotor blades goes into use.

In 1953, a new foundry

In 1956, foundry presses for producing rotors.

In 1960, production of the so-called common line of motors, generator production stopped.

In 1963, 242000 el. motors, 70000 small motors, 190000 irons and 2000 wafer makers, 6700 el. radiators were produced

New administrative buildings were built by the end of the 60s along with the gravity diecasting plant

In 1971, the warehouse

In 1972, the lab and garages

By the beginning of the 80s, all of the present production buildings had been completed.